A Wet Drum Magnetic Separator is a smart and reliable piece of equipment used to remove magnetic materials—mostly iron particles—from slurries (liquid mixtures of finely ground solids and water). It’s a must-have in many industries like mining, ceramics, chemicals, recycling, and paper manufacturing, where separating unwanted metals from valuable materials is key to keeping production lines clean, efficient, and high-performing. These separators are also commonly found in processing equipment Canada suppliers serve, supporting both domestic and export-level operations.

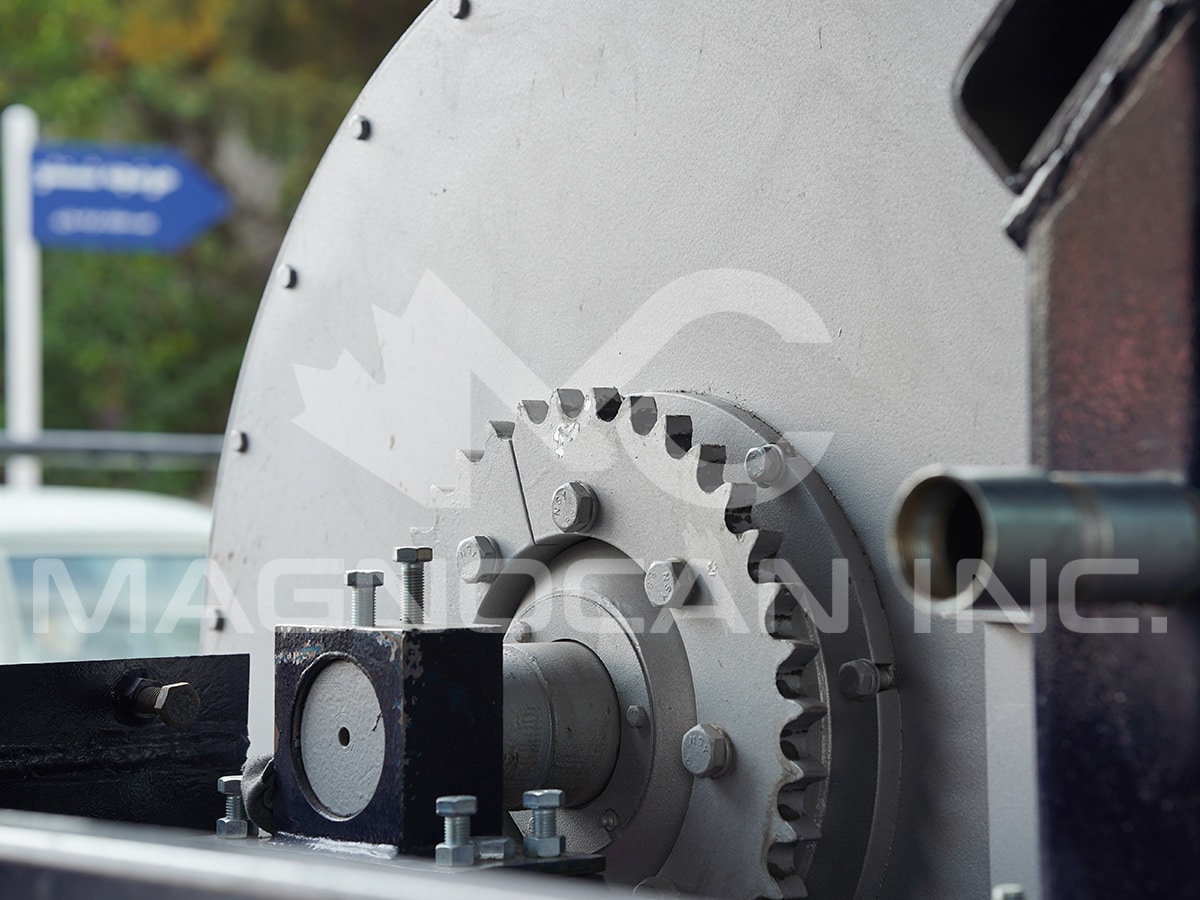

At the heart of the separator is a rotating drum made from stainless steel. Inside the drum sits a strong magnetic system, which can be made of permanent magnets or electromagnets. As the drum spins, it pulls out magnetic particles from the slurry while allowing non-magnetic materials to pass through freely. It’s a continuous, automatic process that boosts product quality and protects other machines in the production line.

What Is a Wet Drum Magnetic Separator and Why Is It Used?

A Wet Drum Magnetic Separator is a highly effective industrial tool designed to separate magnetic and iron-containing particles from wet materials—usually in the form of slurry, a mix of solids and water.

At its core, the machine features a rotating drum fitted with powerful magnets, either permanent or electromagnetic. As the slurry flows through the separator, the magnetic field attracts any magnetic particles, pulling them toward the surface of the drum. These particles cling to the drum as it rotates, eventually being carried to a discharge point where they are removed. Meanwhile, the non-magnetic materials simply flow past the drum and continue on to the next step in the production process.

This type of separation is essential in many industries—such as mining, ceramics, chemicals, and recycling—where removing even small traces of iron can dramatically improve product quality, protect downstream equipment, and increase process efficiency. Whether you’re purifying raw materials or recovering valuable magnetic minerals, a wet drum magnetic separator offers a dependable and continuous solution.

How It Works – In Simple Terms

Slurry flows into the separator, containing both magnetic and non-magnetic particles.The rotating drum attracts and holds magnetic particles using a strong magnetic field.These are carried to a discharge point, while non-magnetic material flows out separately.

Slurry Enters the Separator

The process starts when slurry—containing both magnetic (like iron) and non-magnetic particles—is pumped into the separator’s tank.

Magnetic Particles Get Pulled In

As the slurry flows past the spinning drum, the strong magnetic field inside the drum attracts any magnetic particles. These particles stick to the surface of the drum like metal to a magnet.

Transport and Discharge of Magnetic Particles

The drum slowly turns, carrying the magnetic particles along its outer surface. Once they reach an area where the magnetic field is weaker, they drop off into a separate collection area—cleanly separated from the rest of the material.

Non-Magnetic Particles Move On

The non-magnetic particles simply flow past the drum and continue down the processing line. Since they aren’t affected by the magnet, they remain untouched.

This method helps ensure that only clean, valuable material continues through your process, while unwanted metallic particles are removed efficiently. It reduces equipment wear, saves energy, and helps you get a better, purer final product—all without needing constant attention.

Why Use a Wet Drum Magnetic Separator?

Using a wet drum magnetic separator in your processing line isn’t just about removing iron—it’s about improving the whole operation. Here’s how it makes a real difference:

1. Cleaner, Higher-Quality Output

By capturing unwanted iron and magnetic particles early, you end up with purer materials. Whether you’re working with minerals, chemicals, or ceramics, better raw material means better final products.

2. Protects Your Expensive Equipment

Tiny metal particles can do serious damage to pumps, mills, and other sensitive machines. Removing them early helps prevent wear and tear, avoiding costly breakdowns.

3. Fewer Breakdowns, Lower Maintenance Costs

When your machines don’t get clogged or damaged by metal debris, you save time and money on maintenance. Less downtime means smoother operations and fewer headaches.

4. Longer Lifespan for Your Machinery

Reducing exposure to abrasive metal particles helps your equipment last longer—protecting your investment and improving long-term reliability.

5. Smarter, More Efficient Separation

These separators are designed to do one job—and do it well. They extract magnetic materials with high precision, so you’re not losing valuable product or energy in the process.

6. Lower Energy Consumption

When machines aren’t overloaded with unnecessary material, they run more efficiently. That means less power usage, lower energy bills, and a more sustainable operation.

7. Boosts Overall Productivity

With steady, reliable separation, your entire processing line can operate at higher capacity with fewer interruptions—directly increasing output and profitability.

Whether you’re in mining, recycling, ceramics, or chemicals, a wet drum magnetic separator isn’t just an add-on—it’s a smart, cost-effective tool that improves quality, protects your process, and helps you get more out of every ton of material.

Industrial Applications of Wet Drum Magnetic Separators

Wet Drum Magnetic Separators are essential tools across a wide range of industries where removing iron and magnetic impurities from wet material is critical for product quality, equipment protection, and process efficiency. Their role goes beyond just separation—they help create cleaner products, reduce machine wear, and increase profitability.

Below are some of the key sectors that rely on this technology:

Mineral Processing

- Iron Ore Concentration: Efficiently separates magnetite and hematite to boost purity and recovery.

- Non-Ferrous Mineral Purification: Removes iron particles from materials like feldspar or quartz.

- Value Enhancement: Improves the grade and market value of the processed mineral.

Ceramics and Tile Production

- Slurry Purification: Eliminates iron contaminants from ceramic slurries.

- Better Aesthetic Quality: Prevents dark spots and imperfections in tiles and ceramic ware.

- Glazing & Firing Optimization: Reduces defects during finishing processes.

Chemical Industry

- Process Integrity: Removes metal contaminants from chemical slurries and solutions.

- Purity Assurance: Ensures high-quality raw materials and end-products.

- Equipment Protection: Minimizes wear in sensitive pipelines and tanks.

Paper Manufacturing

- Cleaner Pulp: Improves whiteness and reduces contamination.

- Less Equipment Wear: Prevents iron particles from damaging refiner blades and rollers.

- Consistent Output: Leads to higher-quality paper products.

Recycling Industry

- Efficient Recovery: Extracts magnetic materials from recycled slurries.

- Purity Boost: Enhances the value and usability of recovered materials.

- Sustainability: Supports circular processes and waste reduction.

Food Industry (Special Applications)

- Hygiene Compliance: In certain food lines, separators ensure metal-free slurries.

- Safety Assurance: Meets regulatory standards for food safety and consumer protection.

Tailored Solutions from Magnocan

Magnocan’s Wet Drum Magnetic Separators are designed with flexibility in mind. Each machine is built to meet the unique needs of your production line—whether you prioritize high recovery rates, product purity, or long-term durability.

Technical Highlights

| Feature | Specification |

| Magnet Type | NdFeB (Neodymium), Ferrite, or Electromagnetic |

| Magnetic Field Strength | Adjustable from 700 to 9000 Gauss |

| Drum Diameter | 300 mm to 1200 mm |

| Drum Length | 300 mm to 3000 mm |

| Drum Rotation Speed | Variable from 5 to 30 RPM |

| Construction Material | Corrosion-resistant Stainless Steel 304 or 201 |

| Drum Surface | Rubber-coated or Stainless Steel (abrasion-resistant) |

| Processing Capacity | From 2 tons/hour up to 100+ tons/hour (dry material equivalent) |

| Drive System | Waterproof industrial motor with gearbox for consistent, stable operation |

| Customization Options | Full flexibility: magnet type, size, housing design, rotation speed, integration |

Flow Configuration Options

Magnocan offers three main flow configurations—each tailored for specific feed conditions and separation goals:

1. Counter-Current Flow

Slurry moves opposite to drum rotation

Best for: Maximum recovery of fine magnetic particles

Use Cases: Magnetite tailings recovery, ultra-fine separation

2. Co-Current Flow

Slurry flows in the same direction as the drum

Best for: Higher product purity, coarse magnetic particles

Use Cases: High-grade iron ore concentrate production

3. Semi-Counter Current Flow

Slurry enters at a slight angle to drum rotation

Best for: Balanced recovery and purity

Use Cases: Mixed particle sizes, coal, and recycling lines

Drum Build & Structure

- Covering: Abrasion-resistant rubber or stainless steel (4–6 mm)

- Bearings: Heavy-duty sealed units for extended life

- Magnet Layout: Optimized for full-surface coverage

- Durability: Built to last under tough operating conditions

hoosing the Right Separator

- To find the best magnetic separator for your needs, consider:

- Type of feed and iron content

- Desired throughput (tons per hour)

- Particle size distribution

- Site conditions (humidity, temperature, dust)

- Final product specifications

Magnocan’s expert consultants are available to guide you through every step—from evaluation and selection to implementation.

Request a Quote – Free Expert Consultation

With years of engineering experience and a deep understanding of magnetic separation technologies, Magnocan delivers custom solutions, competitive pricing, and comprehensive after-sales support.Whether you’re designing a new line or upgrading an existing one, Magnocan can help you build a cleaner, more efficient, and more profitable process.

Contact us today for a free technical consultation or to request a customized quote tailored to your production needs.