Lifting magnets are among the most practical and efficient magnetic traps tools used in modern industries. By harnessing the invisible force of magnetism, they enable operators to lift, move, and precisely position ferrous materials—such as steel plates, rods, pipes, and scrap metal—without using mechanical hooks, chains, or slings.

What is a lifting magnet?

Simply put, a lifting magnet is a specialized industrial device that uses a magnetic field to attract and hold ferrous metals securely, allowing them to be lifted and moved safely without physical contact. These magnets can be permanent or electromagnetic, depending on the power source and the application.

Unlike traditional lifting methods that require manual fastening or multiple workers, magnetic lifters provide a contact-free and fast connection between the magnet and the metal surface. This not only speeds up the workflow but also ensures better safety and reduced wear on both equipment and materials.

From steel fabrication workshops in Ontario, to open-pit mining operations in Alberta, shipyards along Canada’s coasts, and recycling plants in urban industrial zones, lifting magnet Canada systems have become a vital part of material handling solutions. They help companies improve productivity, lower operating costs, enhance workplace safety, and reduce downtime — all while providing a more sustainable and energy-efficient lifting method.

However, just like any industrial equipment, lifting magnets also have their limitations and operational considerations. Their performance depends heavily on factors such as the type of material, surface condition, environmental temperature, and the magnet’s rated capacity. Failing to account for these factors can reduce magnetic strength, cause load slippage, or even lead to operational hazards.

This article provides a complete overview of the advantages and limitations of lifting magnets, explaining how they work, why they’re widely used across industries, and what key factors determine their effectiveness in real-world applications. Whether in steel manufacturing, mining, construction, or recycling, understanding these aspects helps ensure safe, efficient, and reliable magnetic lifting operations in any industrial setting.

Why Use Lifting Magnets?

In industrial material-handling operations, time, safety, and efficiency are three critical factors that directly impact productivity and costs.

Traditional lifting methods—such as using chains, slings, hooks, or clamps—require manual attachment and removal for each lift.

This process not only increases labor time and fatigue but also raises the risk of accidents, pinching injuries, or load imbalance during operation.

Lifting magnets solve these challenges with a smarter, faster, and safer approach.

By creating a powerful magnetic field, they directly grip the surface of ferrous metals (like steel or iron), allowing operators to lift and move materials instantly—without physical contact or mechanical locking systems.

This contact-free lifting minimizes surface damage and eliminates the need for multiple workers to attach lifting gear.

In industries like steel fabrication, mining, construction, shipbuilding, and recycling, lifting magnets have revolutionized handling operations by:

- Reducing setup and handling time by up to 60%

- Enhancing workplace safety with secure magnetic grip and easy release mechanisms

- Lowering labor and maintenance costs through simplified operation

- Improving precision and control during positioning or stacking of steel parts

- Eliminating damage to finished metal surfaces during lifting or transfer

Whether it’s moving heavy steel plates in a fabrication plant, loading scrap metal in recycling yards, or positioning components in an assembly line, lifting magnets provide a reliable, energy-efficient, and clean alternative to mechanical lifting methods.

In short, the reason why lifting magnets are used so widely across modern industries is simple:

they combine speed, safety, and savings—three essential pillars of efficient material handling.

Advantages and Limitations of Lifting Magnets in Industrial Applications

Lifting magnets are among the most practical and efficient magnetic handling tools used in modern industries.

By harnessing the invisible force of magnetism, they enable operators to lift, move, and precisely position ferrous materials—such as steel plates, rods, pipes, and scrap metal—without using mechanical hooks, chains, or slings.

Unlike traditional lifting methods that require manual fastening or multiple workers, magnetic lifters provide a contact-free and fast connection between the magnet and the metal surface.

This not only speeds up the workflow but also ensures better safety and reduced wear on both equipment and materials.

From steel fabrication workshops in Ontario, to open-pit mining operations in Alberta, shipyards along Canada’s coasts, and recycling plants in urban industrial zones, lifting magnets have become a vital part of material handling systems.

They help companies improve productivity, lower operating costs, enhance workplace safety, and reduce downtime — all while providing a more sustainable and energy-efficient lifting method.

However, just like any industrial equipment, lifting magnets also have their limitations and operational considerations.

Their performance depends heavily on factors such as the type of material, surface condition, environmental temperature, and the magnet’s rated capacity.

Failing to account for these factors can reduce magnetic strength, cause load slippage, or even lead to operational hazards.

This article provides a complete overview of the advantages and limitations of lifting magnets, explaining how they work, why they’re widely used across industries, and what key factors determine their effectiveness in real-world applications.

Whether in steel manufacturing, mining, construction, or recycling, understanding these aspects helps ensure safe, efficient, and reliable magnetic lifting operations in any industrial setting.

| Advantages of Lifting Magnets | Limitations of Lifting Magnets |

| Fast and contact-free lifting | Limited to ferrous materials only |

| Improves safety and reduces manual labor | Reduced performance on painted or rusty surfaces |

| No damage to metal surfaces | Sensitive to temperature and environment |

| Lower operational costs and zero energy use | Limited lifting capacity per magnet size |

| Easy to operate and maintain | Requires backup system for electromagnets |

Advantages of Lifting Magnets

Lifting magnets have become indispensable tools in modern industrial material handling, thanks to their unique ability to combine speed, safety, and efficiency in one simple device.

Whether used in steel mills, fabrication workshops, recycling plants, or mining facilities, magnetic lifters offer several clear advantages that make them more effective than conventional lifting methods.

1. Faster and More Efficient Material Handling

Lifting magnets allow instant pickup and release of metal materials without the need for hooks, clamps, or chains.

This eliminates the time spent on securing and unfastening loads, enabling operators to move parts continuously and streamline production flow.

Result: Shorter cycle times, higher throughput, and improved operational productivity.

2. Reduced Labor and Operating Costs

Because magnetic lifters can be controlled by a single operator, they significantly reduce manpower requirements.

There’s no need for extra workers to attach or remove lifting gear—saving both time and labor costs.

Additionally, they require minimal maintenance, lowering long-term expenses for industrial operations.

Result: Lower operational costs and higher overall profitability.

3. Improved Workplace Safety

Safety is a top priority in every industrial environment, and lifting magnets provide a secure, mechanical-free connection between the magnet and the load.

By eliminating slings, chains, or clamps, the risk of load slippage, pinching, or entanglement is greatly reduced.

Many models also feature safety locks, load indicators, and automatic release systems to prevent accidental drops.

Result: Safer working conditions and fewer lifting-related accidents.

4. No Damage to Metal Surfaces

Unlike hooks or mechanical grips that may dent, scratch, or deform steel plates, lifting magnets apply uniform magnetic force across the entire contact area.

This is particularly valuable when handling precision-machined parts, polished sheets, or coated materials, where surface integrity must remain intact.

Result: Smooth, damage-free lifting and reduced product waste.

5. Energy-Efficient and Eco-Friendly Operation

Permanent lifting magnets require no external electricity to operate, relying entirely on the natural magnetic field of rare-earth magnets such as neodymium (NdFeB).

This not only reduces energy consumption but also ensures continuous operation—even during power failures.

Result: Zero power cost, high reliability, and sustainable performance.

6. Versatile for Multiple Applications

From flat steel sheets to round pipes, machine parts, or scrap metal, lifting magnets can handle a wide variety of ferrous shapes and sizes.

Specialized designs, such as battery-powered or electromagnetic models, further expand their flexibility for automated, outdoor, or heavy-duty environments.

Result: One solution for multiple lifting tasks across industries.

Limitations of Lifting Magnets

Although lifting magnets provide remarkable efficiency and safety benefits in material handling, they also come with certain limitations and operational constraints that must be considered for safe and reliable use.

Understanding these limitations helps prevent accidents, avoid downtime, and extend the lifespan of both the magnet and the equipment.

1. Only Effective on Ferrous Materials

Lifting magnets are designed to work exclusively with ferrous metals such as iron, mild steel, and certain alloys that contain magnetic properties.

They cannot lift non-ferrous materials like aluminum, copper, or stainless steel (austenitic grades).

Solution: Use mechanical lifters or vacuum systems for non-magnetic materials.

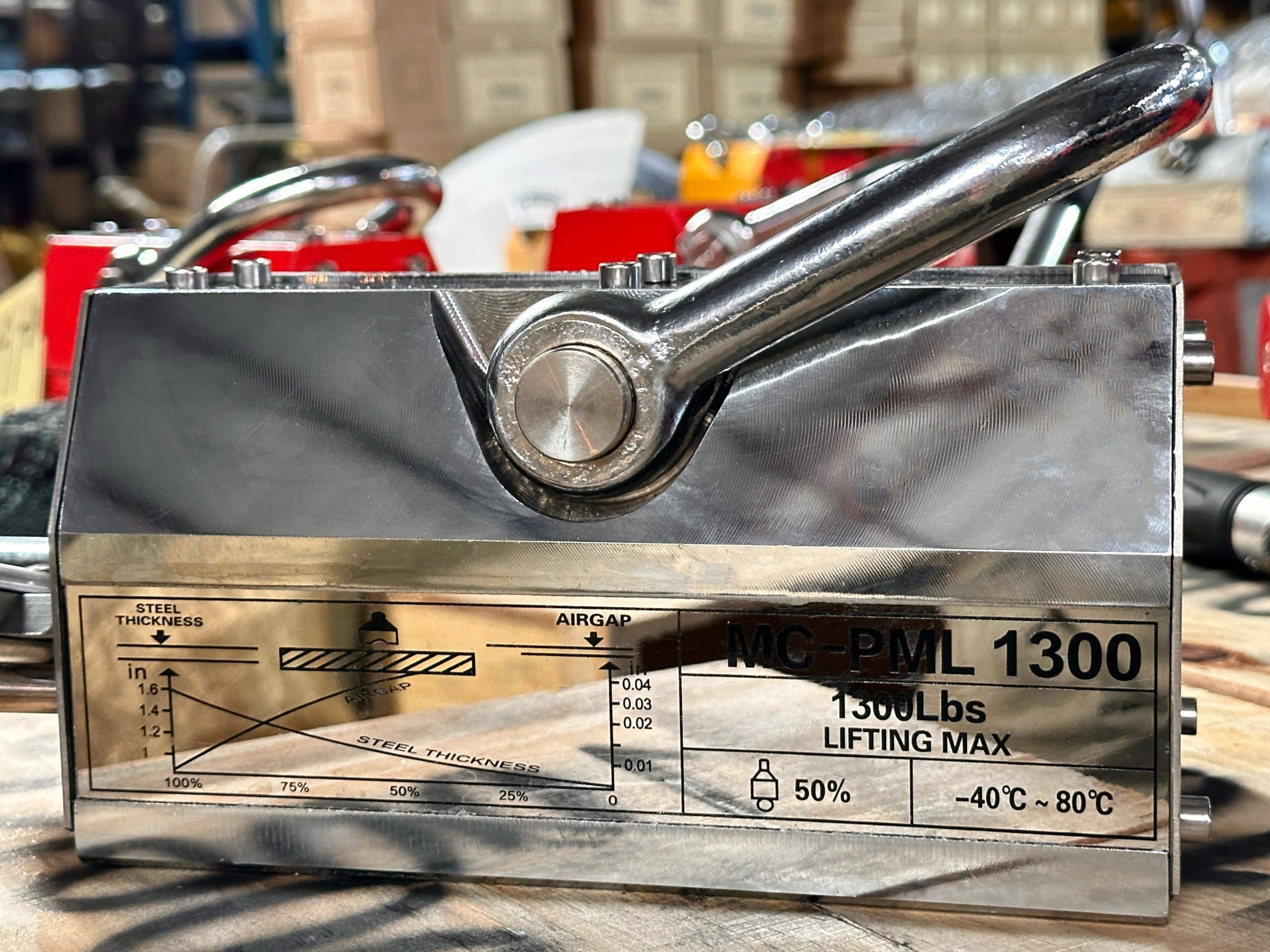

2. Limited Load Capacity

Each magnet has a rated lifting capacity that depends on its size, design, and magnetic strength.

However, actual lifting performance can vary based on several factors, including:

- Material thickness and composition

- Surface smoothness or roughness

- Air gaps caused by paint, rust, or dirt

- Contact area between the magnet and the load

Exceeding the rated capacity or using magnets on uneven surfaces can cause load slippage or incomplete lifting.

Best Practice: Always choose a magnet with at least 25–50% higher rated capacity than the expected load weight.

3. Sensitivity to Environmental Conditions

The magnetic field strength and holding capacity of a lifting magnet can be affected by its surrounding environment.

Conditions such as high temperature, moisture, dust, or vibration can reduce the magnet’s performance and lifespan.

Temperatures above 80°C (176°F) may cause demagnetization in permanent magnets.

Moisture or corrosion on the metal surface can reduce contact efficiency.

Dust or oil can create small air gaps that weaken magnetic attraction.

Solution: Use sealed, corrosion-resistant housings or temperature-stable magnetic materials in harsh environments.

4. Power Dependency in Electromagnetic Lifters

Unlike permanent magnets, electromagnetic lifting magnets require a continuous power supply to maintain their magnetic field.

A sudden power failure or voltage drop can instantly deactivate the magnet, causing the load to release unexpectedly.

Solution: Use models with battery backup systems, safety interlocks, or fail-safe holding circuits to prevent accidental load drops.

5. Safety Margin Requirements

Lifting magnets must always be used within safe load limits.

Even under ideal conditions, it’s essential to apply a safety factor (typically 2:1 or higher) to compensate for variations in material quality and surface conditions.

Ignoring these safety margins can lead to overloading, slippage, or magnet fatigue over time.

Recommendation: Follow manufacturer-rated capacity and maintenance guidelines strictly.

Material Handling – Cost Reduction – Productivity

In modern industrial environments, the success of any operation depends heavily on how efficiently materials are moved, stored, and positioned.

Lifting magnets have transformed material handling by providing a faster, safer, and more cost-effective alternative to traditional lifting systems.

Whether used in steel fabrication workshops, foundries, mining sites, or recycling plants, magnetic lifters simplify the entire process of handling heavy metal components—leading directly to cost reduction and productivity improvement across all stages of production.

| Parameter | Traditional Lifting Tools | Lifting Magnets |

| Setup time | Long (requires manual fastening) | Instant (magnetic grip) |

| Operators needed | 2–3 | 1 |

| Surface damage | Possible (scratches/dents) | None |

| Power consumption | High (mechanical/electric) | Zero for permanent magnets |

| Safety level | Medium | High |

1. Streamlined Material Handling

Traditional lifting equipment like chains, hooks, or clamps requires manual adjustment and repeated fastening for each load.

In contrast, lifting magnets allow operators to pick up and release metal parts instantly.

This reduces downtime between lifting cycles, minimizes human effort, and speeds up workflow.

Result: Shorter handling cycles and faster throughput in production lines.

2. Cost Reduction Through Efficiency

Because lifting magnets operate without mechanical contact or complex rigging systems, maintenance costs drop dramatically.

They also reduce the number of operators needed to perform lifting tasks—cutting labor expenses and improving process reliability.

Permanent lifting magnets, in particular, require no electrical power, which means zero energy consumption and lower long-term operational costs.

Result: Lower total cost of ownership (TCO) and improved return on investment (ROI).

3. Increased Workplace Productivity

The combination of quick setup, reduced labor, and smooth operation leads to a measurable increase in productivity.

Factories using magnetic lifters can move more material in less time while maintaining high precision and safety.

Additionally, modern magnetic lifters are designed for multi-directional lifting—handling both flat and round components efficiently.

Result: Higher daily output with fewer interruptions and minimal material damage.

4. Enhanced Safety and Ergonomics

Reducing manual lifting not only cuts costs but also improves operator safety and ergonomics.

Workers spend less time positioning loads manually, lowering the risk of back injuries, hand pinches, and dropped materials.

This contributes to a safer, more efficient, and more sustainable working environment.

Result: Fewer accidents, less fatigue, and a more productive workforce.

Environmental Factors Affecting Lifting Magnet Performance

While lifting magnets are designed to deliver reliable and consistent performance in various industrial environments, their magnetic strength and operational efficiency can be significantly influenced by environmental factors.

Conditions such as temperature, humidity, dust, vibration, and corrosion can alter the magnetic field, reduce lifting capacity, or cause long-term mechanical wear.

Understanding these environmental effects is essential for ensuring safe operation, consistent performance, and extended equipment life in demanding industrial applications.

Temperature Effects

Temperature is one of the most critical environmental variables affecting lifting magnets.

Both permanent magnets and electromagnets experience a change in magnetic field strength when exposed to extreme heat or cold.

High Temperatures (Above 80°C / 176°F):

Can lead to partial demagnetization in permanent magnets such as neodymium (NdFeB), reducing their holding power.

Continuous exposure can also weaken adhesive joints and mechanical housings.

Low Temperatures (Below -20°C / -4°F):

May cause brittleness in magnetic materials and increase internal stress, especially in outdoor environments.

Solution: Use temperature-stabilized materials like Samarium Cobalt (SmCo) for high-heat applications, or ensure proper thermal insulation for electromagnets.

2. Humidity and Corrosion

High humidity levels or exposure to water, steam, or chemical vapors can cause corrosion of the magnetic surface and internal components.

This corrosion not only weakens the magnetic field but also increases the risk of mechanical failure over time.

Permanent magnets made from neodymium are particularly prone to corrosion if not properly coated.

Solution:

Use stainless steel housings (304/316) or epoxy-coated magnetic assemblies for humid or corrosive environments — especially in wet magnetic drum separators and marine applications.

3. Dust, Oil, and Surface Contamination

The performance of a lifting magnet depends on the quality of surface contact between the magnet and the material being lifted.

Dust, oil, rust, or paint layers create air gaps, which significantly reduce the magnetic attraction force.

Even a 0.5 mm gap caused by dirt can decrease the lifting capacity by up to 30–40%.

Solution:

Maintain regular cleaning schedules, ensure smooth, debris-free surfaces, and implement protective covers in dusty or oily environments.

4. Vibration and Mechanical Stress

Continuous vibration or mechanical shock (common in mining or construction) can cause misalignment between the magnet and its mounting base.

Over time, this may lead to loosening of bolts, magnetic fatigue, or structural cracking in the housing.

Solution:

Use anti-vibration mounts, reinforced brackets, and perform routine alignment checks to maintain optimal performance.

5. Electrical Interference (for Electromagnets)

Electromagnetic lifting systems can be affected by electrical noise, unstable voltage, or interference from nearby heavy machinery.

Such interference may cause fluctuations in current, leading to inconsistent magnetic force or accidental release of loads.

Solution:

Install voltage regulators, shielded cables, and backup power systems to maintain stable magnetic field strength in critical operations.

Summary

Lifting magnets have become a cornerstone of modern industrial material handling, offering a perfect balance between efficiency, safety, and cost-effectiveness.

Their ability to lift and move ferrous materials without hooks or slings makes them an ideal choice for steel fabrication, mining, construction, and recycling industries.

The advantages—including faster operation, reduced labor, energy efficiency, and improved safety—make lifting magnets one of the most practical tools in any production environment.

However, understanding their limitations, such as material restrictions, load capacity, and environmental sensitivity, is crucial to ensure safe and reliable performance.

By choosing the right magnet type (permanent, electromagnetic, or hybrid) and maintaining proper operating conditions, industries can achieve:

- Higher productivity

- Lower operational costs

- Enhanced workplace safety

- Longer equipment lifespan

In conclusion, when properly selected and maintained, lifting magnets represent a powerful solution for efficient and sustainable material handling—turning the power of magnetism into measurable industrial advantage.

Frequently Asked Questions (FAQ)

1. What is a lifting magnet and how does it work?

A lifting magnet is an industrial device that uses magnetic force to lift and move ferrous materials such as steel plates, rods, or scrap metal.

It creates a magnetic field that grips the material securely, allowing for safe, contact-free lifting.

Depending on the model, lifting magnets can be permanent, electromagnetic, or battery-powered.

2. What are the main advantages of using lifting magnets?

Lifting magnets provide several key benefits:

they speed up material handling, reduce labor costs, improve safety, and prevent surface damage.

Permanent models require no external power, making them both energy-efficient and eco-friendly—especially in lifting magnet Canada applications where efficiency and reliability are crucial.

3. What are the common limitations of lifting magnets?

Although highly efficient, lifting magnets only work with ferrous metals such as iron and steel.

Their performance may decrease due to surface rust, paint, or uneven contact.

Environmental conditions like high temperature, humidity, or power failure (in electromagnets) can also affect performance.

Using the right magnet type and regular maintenance ensures stable operation.

4. How do environmental factors affect lifting magnet performance?

Environmental elements such as temperature, moisture, dust, and vibration can significantly impact magnetic strength.

For example, high heat can demagnetize permanent magnets, and moisture can cause corrosion or slippage.

To prevent this, industries use stainless-steel housings, epoxy coatings, and anti-vibration mounts in harsh environments.