Lifting magnets, also known as magnetic lifters, have become an indispensable tool in industries such as steel manufacturing, mining, shipbuilding, automotive, and heavy machinery. By generating a powerful magnetic field, they allow operators to handle heavy sheets, billets, scrap, and other ferrous materials quickly, safely, and with minimal manpower.

Despite their simple design and reliable operation, lifting magnets can be misused in ways that reduce efficiency, increase maintenance costs, and even create dangerous situations. Choosing the right model, understanding its technical specifications, and investing wisely in the price of a lifting magnet is only part of the equation. Correct daily use and proper care are equally important.

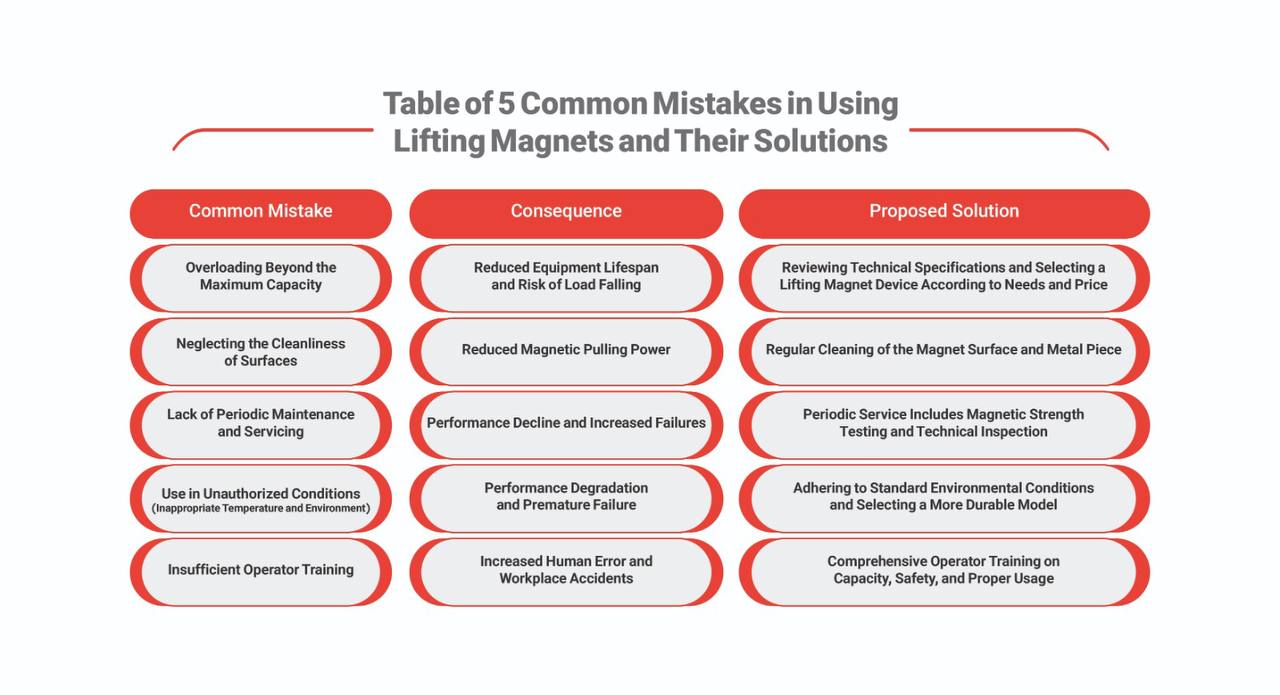

In this guide, we will cover the five most common mistakes operators make when using lifting magnets, along with practical solutions. By applying these tips, you can extend the service life of your magnet, reduce downtime, and ensure your investment delivers maximum value.

Mistake:

Perhaps the most dangerous mistake when using a lifting magnet is overloading it beyond its rated capacity. Some operators assume that “a little extra weight” will not matter, but magnets are precisely engineered devices. Consistently exceeding the rated load puts stress on the magnet’s internal components, reduces magnetic efficiency, and creates a serious safety hazard. In worst-case scenarios, the load may detach mid-lift, causing damage to equipment, production delays, or even workplace injuries.

Solution:

The solution is simple: never exceed the rated capacity indicated in the technical specifications. Before purchasing, carefully evaluate the type and weight of materials you will be lifting on a daily basis. If you frequently handle heavy steel plates or billets, investing in a higher-capacity magnet is the safest choice. Although such a unit may increase the lifting magnet price, it prevents accidents and long-term maintenance costs. Remember: saving money by underestimating your capacity requirements often leads to much higher expenses later.

Ignoring Clean Surfaces on Magnet and Material

Mistake:

Another common mistake is neglecting the cleanliness of the contact surfaces. Dust, oil, paint, rust, and welding slag all act as barriers between the lifting magnet and the load. Even a thin layer of contamination can significantly reduce the magnet’s holding force. Operators often underestimate this issue, but in practice, poor surface conditions are one of the leading causes of reduced performance and unsafe lifting.

Solution:

Always ensure both surfaces—the magnet face and the load surface—are clean and smooth before lifting. Implementing a routine cleaning step in your operation will dramatically improve safety and efficiency. For industries prone to corrosion or oil contamination, it is wise to choose magnets with special protective coatings or polished faces that are easier to maintain. When considering the price of a lifting magnet, don’t just focus on initial cost—evaluate the long-term benefits of a model that requires less frequent cleaning and delivers more consistent performance.

Poor Maintenance and Lack of Regular Servicing

Mistake:

Because lifting magnets are robust and durable, many users wrongly assume that they do not require maintenance. Over time, however, this neglect leads to a gradual loss of magnetic strength, wear and tear on safety locks, and deterioration of electrical systems (for electromagnets). The result is not only costly repairs but also the risk of sudden failure during operations.

Solution:

Proper maintenance is the backbone of safe magnet use. Operators should:

Inspect magnets visually before each shift.

Regularly measure lifting capacity to confirm it still meets rated values.

For electromagnets, check wiring, switches, and batteries.

Schedule professional servicing at least twice a year to detect hidden issues before they escalate.

When comparing the lifting magnet price, always consider after-sales support, availability of spare parts, and service options. A magnet that seems cheaper at first but offers no service support will cost more in downtime and repairs over its lifetime. Magnocan provides clear maintenance guidelines and expert service assistance, ensuring your investment delivers long-term value.

Using in Harsh or Unsuitable Environments

Mistake:

Lifting magnets are designed for specific environmental conditions. Using them in extreme heat, high humidity, or corrosive settings without proper protection reduces performance and shortens lifespan. For example, excessive heat can cause permanent demagnetization, while chemical exposure can corrode the magnet’s housing. Unfortunately, many operators overlook these limitations until problems appear.

Solution:

Understand your working environment before selecting a lifting magnet. If you are operating in foundries, shipyards, or offshore platforms, you need a magnet built with heat-resistant materials and corrosion-proof coatings. While these specialized models may increase the upfront lifting magnet price, they deliver far greater durability and safety in challenging conditions. Investing in the right equipment from the start ensures fewer breakdowns, less downtime, and lower replacement costs.

Insufficient Operator Training

Mistake:

Even the most advanced lifting magnet cannot compensate for a poorly trained operator. Without proper knowledge of load limits, safety features, and correct positioning techniques, workers may misuse the equipment, leading to unsafe lifts, accidents, or damage to both the magnet and the load. Training is often overlooked in busy industrial environments, yet it is a key factor in workplace safety.

Solution:

Every operator must receive comprehensive training before using lifting magnets. Training should cover:

- Reading and understanding rated capacity charts.

- Correctly positioning the magnet for maximum contact.

- Engaging and disengaging safety locks.

- Recognizing when a load is unsafe to lift.

- Following emergency procedures.

When reviewing the price of a lifting magnet, ask your supplier about training and technical support. At Magnocan, we don’t just provide high-quality lifting magnets—we also equip your team with the knowledge they need to use them effectively. This combination of reliable equipment and skilled operators ensures maximum safety and performance in every lift.

When comparing the price of a lifting magnet, factor in not only the cost of the unit but also the training and support services offered by the supplier. At Magnocan, we provide guidance to ensure operators use our products safely and effectively.

Maintenance Guidelines for Lifting Magnets

Proper care ensures consistent performance, extended lifespan, and reduced risk. Follow these practices:

- Daily Maintenance

- Inspect for cracks, deformation, or unusual wear.

- Verify safety locks are functional.

- Remove dust, rust, oil, and paint before operation.

- Periodic Maintenance

- Test magnetic lifting capacity monthly.

- For electromagnets: check electrical connections, power supply, and battery life.

- Apply protective oil or anti-corrosion coating as needed.

- Long-Term Maintenance

- Conduct a professional inspection every 6 months.

- Replace worn-out parts before they fail.

- Keep records of maintenance for compliance and safety audits.

By integrating these practices into your routine, you’ll maximize ROI and ensure the lifting magnet price you paid translates into long-term value.

Conclusion

Lifting magnets are powerful, reliable tools, but only when used correctly. By avoiding these five common mistakes—overloading, ignoring surface cleanliness, poor maintenance, unsuitable environments, and lack of training—you can dramatically improve both safety and efficiency.

When considering the price of a lifting magnet, remember that value comes not just from purchase cost, but from durability, safety, after-sales service, and proper training.