The magnetic drum separator is one of the most essential pieces of equipment in mineral processing, crushing, and separation lines. Its primary function is to remove iron and other magnetic particles from various materials. These separators are widely used in mining operations, mineral processing plants, concentrate production facilities, and even in chemical and recycling industries. While many people assume that the efficiency of these machines depends solely on the magnet strength or drum quality, the reality is that the main determining factor is the correct design of the housing (Tank / Housing).

The housing is far more than just a protective cover—it’s a precise process tank that plays a critical role in the machine’s performance. A well-designed housing controls the flow of feed (mineral slurry) into the separation zone, manages the residence time of particles in the magnetic field, directs the exact path for concentrate and tailings, and ultimately optimizes separation efficiency based on the material type, processing stage, and magnetic content of the feed.

Simply put, even the strongest magnets cannot guarantee optimal performance without the right housing design. Selecting and designing the housing requires careful consideration of factors such as production line capacity, type of mineral, operating conditions (humidity, temperature, abrasiveness), and final processing objectives. This is why magnetic drum separators are considered a vital part of mineral processing equipment, directly influencing overall efficiency and product quality.

Types of Magnetic Drum Housings

Magnetic drum housings are designed in various styles to suit different operational needs and material types. Some are standard models for general processing lines, while wear-resistant housings are ideal for abrasive materials such as iron ore. Stainless steel housings are often used in wet environments or food and chemical industries to resist corrosion. Compact housings are available for limited-space applications, and fully customized housings can be engineered to optimize capacity, feed type, and operating conditions. The three main housing configurations are:

Operation: The feed flows in the same direction as the drum rotation. Magnetic particles are captured as they move along the drum.

Features: Shorter residence time in the magnetic field; medium to low-magnetic particles have less chance to be captured; simple design with high throughput.

Applications: Rougher stage where coarse, high-grade particles need to be separated quickly; ideal for high-capacity lines.

2. Counter Current Tank

Operation: The feed flows against the drum rotation, increasing particle residence time in the magnetic field.

Features: Higher recovery of fine and low-grade particles; more precise separation compared to Concurrent tanks.

Applications: Cleaner or scavenger stages where maximizing purity and recovering remaining particles is the goal; suitable for fine feed with lower magnetic content.

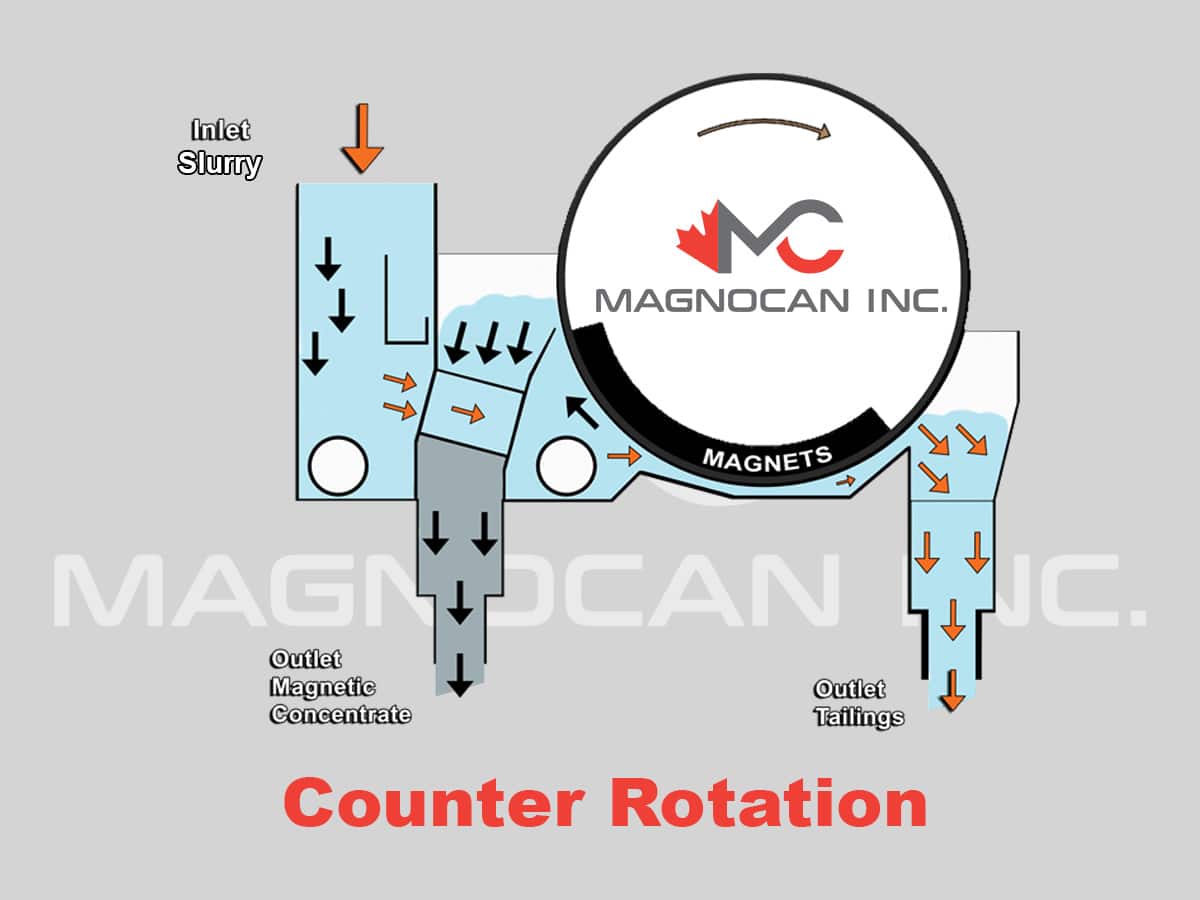

3. Counter Rotation Tank

Operation: Feed enters from the front while the drum rotates in the opposite direction, combining the benefits of both Concurrent and Counter Current designs.

Features: High recovery efficiency with adequate capacity; more complex design.

Applications: Intermediate stages where both recovery and throughput are critical.

Quick Comparison:

Housing Type Feed Direction Residence Time Recovery Efficiency Main Application

Concurrent With Drum Short Lower Rougher

Counter Current Against Drum Long High Cleaner / Scavenger

Counter Rotation Mixed Medium-Long Very High Intermediate / High Capacity

| Housing Type | Feed Direction | Residence Time | Recovery Efficiency | Main Application |

| Concurrent | With Drum | Short | Lower | Rougher |

| Counter Current | Against Drum | Long | High | Cleaner / Scavenger |

| Counter Rotation | Mixed | Medium-Long | Very High | Intermediate / High Capacity |

The Impact of Housing Design on Separation Efficiency

The housing isn’t just a protective shell; it’s the core of the process, controlling particle paths, residence time, and behavior in the magnetic field. Proper design directly affects separation efficiency, product quality, and equipment lifespan.

Key Factors:

- Feed Flow Path: Must ensure uniform particle movement to prevent accumulation, which reduces magnetic contact.

- Feed Entry and Exit Angles: Proper angles increase magnetic particle residence time and ensure smooth discharge of concentrate and tailings.

- Housing Length and Volume: Determines residence time for fine and coarse particles to achieve full separation without clogging.

- Liners and Internal Material: Wear-resistant liners reduce friction, ensure smooth feed flow, save energy, and protect the drum.

- Sealing and Protection: Prevents dust, moisture, and fine particles from entering bearings and mechanical parts, maintaining efficiency.

- Compatibility with Process Stage: Matching the housing type (Concurrent, Counter Current, Counter Rotation) with the processing stage ensures optimal recovery and product purity.

Key Considerations for Choosing the Right Housing

- Feed Type and Particle Size: Coarse, high-grade feed is ideal for Concurrent tanks; fine or low-magnetic feed benefits from Counter Current or Counter Rotation.

- Processing Stage: Rougher for rapid removal, Cleaner for purity, Scavenger for maximum recovery.

- Magnetic Field Strength and Residence Time: Housing length should match the magnetic field to ensure proper separation.

- Construction Quality: Durable, wear-resistant materials extend equipment lifespan.

- Maintenance Access: Modular design with easy access to bearings, shafts, and internal parts minimizes downtime.

- After-Sales Support and Spare Parts: Reliable brands like Magnocan provide engineering support, quick spare parts delivery, and customized solutions for specific industry needs.

Choosing the right housing involves evaluating feed characteristics, processing stage, magnetic strength, construction quality, and service support. The proper housing maximizes separation efficiency, extends equipment life, and reduces operational costs.

Magnocan’s Expertise in Magnetic Drum Housings

Magnocan Canada has extensive experience in designing and manufacturing state-of-the-art magnetic processing equipment, providing solutions that meet the highest standards of efficiency and reliability. Our offerings include custom housing designs—Concurrent, Counter Current, and Counter Rotation—carefully engineered to match the specific feed type, particle size, and production line capacity of your operation. Each housing is built from durable, wear-resistant materials that ensure a long service life while minimizing maintenance requirements and operational downtime.

In addition to delivering high-quality equipment, Magnocan provides professional installation and comprehensive staff training, ensuring your team can operate and maintain the systems safely and efficiently. Our commitment doesn’t stop at delivery; we offer technical support and fast spare parts supply, so your production line keeps running smoothly without costly interruptions.

With Magnocan’s expertly engineered magnetic drum housings, your mineral processing lines benefit from higher separation efficiency, improved product purity, and optimized operational costs. By integrating advanced design, robust construction, and responsive support, Magnocan ensures that every drum separator performs at its peak, helping your facility maximize recovery rates and achieve consistent, high-quality output.